|

NINGBO ORIENTAL MACHINERY OF POWER CO.,LTD

|

underground cable handling equipment underground cable pusher

| Price: | 3000.0~5000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

we developed 8KN cable pusher to meet the developing project demand. It can improve the installment quality and process efficiently with less noise an

1.Introduction

With the rapid development of the world economy and widely use of the electrical underground cable, the cable installment can take advantages of underground tunnels of street, bridge , park etc to directly bury or in conduit to occupy less area without affecting urban construction and aesthetics.

Considering the cable sectional area is getting bigger, we developed 8KN cable pusher to meet the developing project demand. It can improve the installment quality and process efficiently with less noise and light weight.

2.Parameters

Model number | DLSSJ8A |

Motor model | JW7134.B3 |

Power(KW) | 2X0.75 |

Rated voltage(V) | 380 |

Motor speed(rpm) | 1400 |

Applied cable diameter(mm) | Ø50~200 |

Rated linepull(KN) | 8 |

Pulling speed (m/min) | 6.5 |

Clamping direction | Parallel |

Dimension(mm) | 1000X657X464 |

Weight(KG) | 220 |

3.Application

This pusher is applied for cable diameter from 50~200mm XLPE, oil filled power cable and communication cable, with the help of ground rollers to work by series connection with a group of pushers. And this pusher can also work as an auxiliary puller in the terminal.

4.Structure

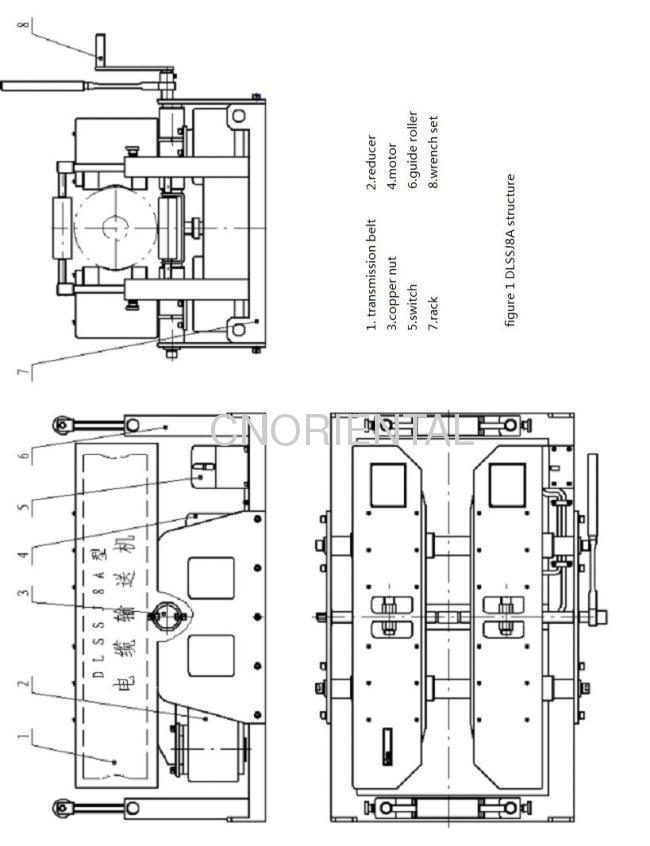

This product adopts double belts power transmission structure in left-right structure to protect the cable insulation while transmission with excellent performance, small size, light weight, easy to operate. It consists of motor, reducer, transmission belt, clamping device, guide rollers, rack and other components (see figure 1)

Each cable puller has a 70m power supply and a sub controller , each 6~10 sets controlled by a Main controller

1)70m power supply

2) sub controller

3) Main controller

Customer in Singapore

When the decision is made to "Go Underground" on a new distribution system,

there are many different areas to consider prior to construction. In the following

paper, we would like to suggest some of these areas for your consideration in

regards to equipment and procedures for underground cable installation.

The three most common methods of cable placement are Direct Buried, Cable

in Conduit, and a Total Conduit System. Most Utilities are currently using one

or more of these methods with various degrees of success.

The first system or method commonly undertaken is the Direct Buried method.

As this system matures, a few questions come to the surface. How much care

was taken in preparation of the trench? How was the cable placed in the

trench? How does different cables react to different soils and ground

conditions? How complicated is it to replace damaged or faulted cable? When

a fault or damage caused by digging occurs, it is very time consuming to open

the trench and make repairs. All these factors and many more affect the

reliability and life of the conductor.

3

Due to these and other conditions, the Cable in Conduit method is considered

in some areas. The cable is placed in a conduit during the manufacturing

process, and this conduit protects the conductor as it lies in the trench, giving it

longer life. However, most of the same questions occur when using the C.I.C.

method as occurs when using the Direct Buried method.

The particular method we would like to discuss in this paper is the Total

Conduit System.

We offers:

overhead stringing puller tensioner

Stringing pulley blocks

Come along clamps

3T 5T diesel gasoline powered winch

underground cable sender, cable pusher, cable feeder, cable puller and rollers

hydraulic drum jack , reel stand, reel elevator

Anti twist steel wire rope

Duct rod, duct rodder

Gin pole

About NINGBO ORIENTAL MACHINERY OF POWER CO.,LTD

We supply various series of equipments and tools for overhead and underground power line transmission installation totally over 2000 products since 1988. Till now we have established business relationship with nearly 5000 power and telecom utilities in China as well as 40 countries world-wide.

1988: Ningbo Oriental Machinery of Power Co., Ltd established

1998: Passed factory management: ISO 9001 International Quality Management System.

2000: Approved by Nation Grid as "Sole Manufacturer of Electric Power Construction Equipment"

2004: Invested 6.5 billion RMB to build a new industy zone covering 105,000 m2.

2006: Gained "Manufacture license of special equipment people's republic of China" by General Administration of Quality Supervision, Inspection and Quarantine of the People's Republic of China"for producing puller ,tensioner and gin pole etc.

2007: confirmed by "China Electricity Council", awarded the first "Key Manufactory of Power Construction Equipment" in China.

2007~2011: Awarded "China qualified famous brand", "Ningbo famous brand", " National Technology Innovation quality management advanced company", "Ningbo top 100 manufacture", "AAA credit enterprise" , " Nation High technology enterprise"

2011:Still now, we have over 400 staff, including one expert enjoying special allowance from State Council, 15 senior engineers, 23 engineers, 34 assistant engineers and 19 senior technicians.

Testing facilities

We invest large number of funds into developing new products and enhancing quality of products every year. After moved to the new industry zone, we have invested over 200 million yuan accumulatively, introducing lots of advanced production equipment and facilities. Now we have:

218 sets of various production equipment

a 40-meter high testing tower (load:40t) and 4000m2 of outdoor testing field which is suitable for the simulated test of 300KN hydraulic pullers, 4*45KN hydraulic tensioners, electrical crossing structures, emergency restoration towers and gin poles;

1000KN horizontal tensile tester and 600KN multifunctional vertical tester which is fit for the tensile test of construction tools and machines of transmission lines up to 1000KV.

35MPa hydraulic testing table ensures the reliable hydraulic system and the more smooth development of hydraulically driven equipment, like pullers and tensioners